The standard procedure for a successful camera inspection is to first specify the input requirements in detail and find out all the necessary details. At first glance, it may seem that some questions are too detailed and the answers do not matter much, but the omission of even one single aspect can result in an unreliable or even non-functional camera system.

Only after a thorough initial analysis of all optical inspection requirements does the first concept design and selection of suitable lighting, optics and industrial or smart cameras follow. We also carry out practical testing of the designed system in our office. In this way, we verify the correctness of our concept and equipment selection under controlled conditions. The results of this testing will be available to you upon completion and we can decide together on the next steps.

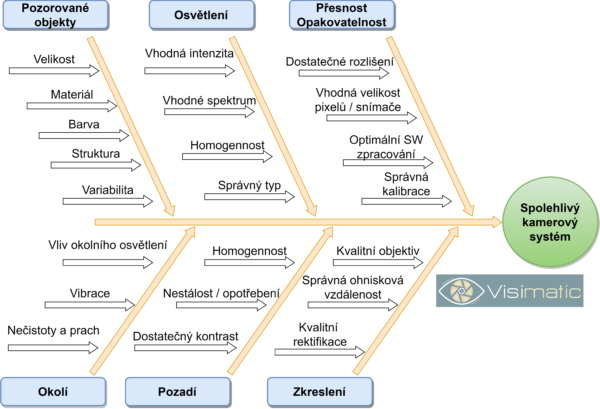

We use a variety of tools to develop an appropriate camera inspection concept, one of which is the Ishikawa diagram, which is one of the seven quality improvement tools.

Pokud máte zájem o bližší informace, nebo chcete s námi probrat využití kamerového systému i ve Vašich aplikacích, neváhejte nás kontaktovat!